soft packaging solvent free plastic-plastic compound equipment

Equipment appearance

Advantages of technology

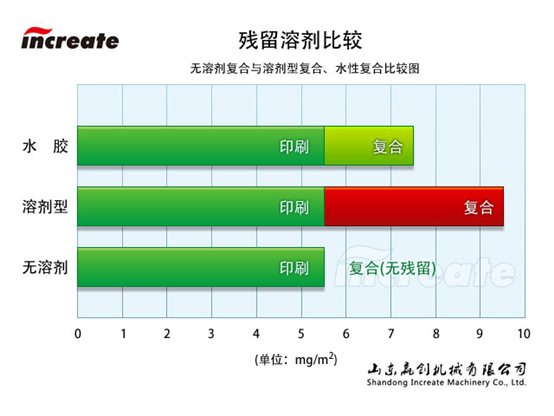

- In compound material, no solvent residual, especially as to meet the requirements of modern health of food and pharmaceutical packaging.

- In the production process there’s no volatile solvent emissions, no pollution to the atmospheric environment, excellent production environment.

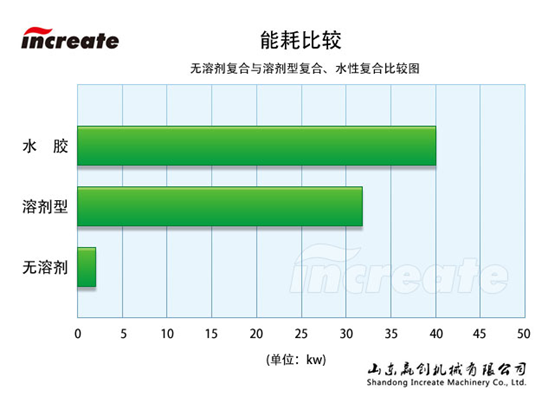

- Because they do not use the conventional drying system, therefore can significantly reduce energy consumption, low production cost.

- Coating glue and total cost has certain decrease than existing technology.

- Machine speed fast, small footprint, no fire and explosion risk.

Solvent-free compound compared with solvent-based compound, water-based compound

| Item | Solvent-based compound | Water-based compound | Solvent-free compound |

|---|---|---|---|

| Offer glue | Artificial mixing | Sometimes artificial mixing | Automatic |

| Coating | Anilox roll | Anilox roll | Smooth roll |

| Coating weight | Not adjustment online | Not adjustment online | Adjustment online |

| Drying | Have drying tunnel | Have drying tunnel/high temperature | No drying tunnel |

| Speed | Intermediate speed | Intermediate and low speed | High speed |

| Winding /Unwinding | Artificial /semi-automatic | Artificial /semi-automatic | Artificial /semi-automatic |

| Cleaning | Anilox roll/glue tray | Anilox roll/glue tray | Smooth roll |

| Degree of automation | Intermediate | Intermediate | High |

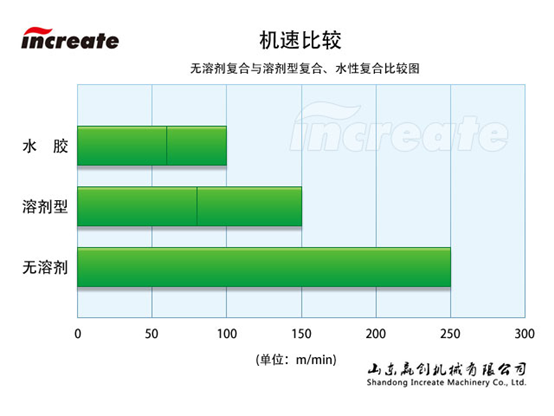

Machine Speed compare

Energy Consumption compare

Residual Solvents compare

The range of composite material and the requirement of surface tension

Solvent-free plastic- plastic laminating machine can be composite substrates are mainly

BOPP,PET,Nylon,CPP,PE,VMPET,VMCPP,PVC,paper,etc,base material is generally applied thickness in 7um-120um (According to the equipment).

The surface tension of the BOPP, PE, CPP, VMCPP general than 38 dyne;

PET film surface tension must be more than 48 dyne;

BOPA(NY)、PVDC and so on must up to 52 dyne.

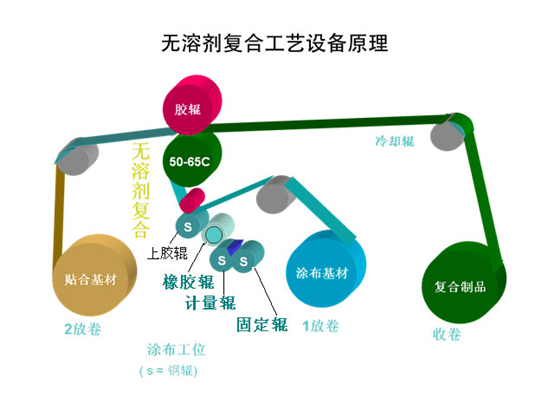

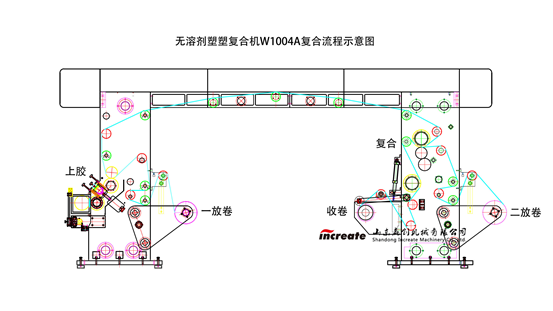

Solvent-free plastic- plastic laminating machine equipment principle

Solvent-free plastic- plastic laminating machine compound process diagram

Solvent-free plastic- plastic laminating machine specification

| Item | Parameters |

|---|---|

| Compound speed | 10-400m/min(According to base material, glue features) |

| Compound width | 600mm-1050mm |

| Unwinding diameter(Max) | Φ800 |

| Winding diameter(Max) | Φ1000 |

| Base width(Max) | 1050mm |

| Paper tube length(Max) | 1050mm |

| Paper tube standard | Inner diameter Φ76mm×Outer diameterΦ92mm |

| Winding paper core | 3 Inches |

| Guide roller length | 1100mm |

| Coating weight | 0.7~2.7g/m2 |

| Composite pressure | 700kg/Full width |

| Composite roll temperature | 5~60℃ |

| Preheat roll temperature | 5~50℃ |

| Total Power | About 45KW |

| Power supply | Three-phase five-wire 380V 50Hz |

| Air pressure | 0.6Mpa |

| Equipment weight | About 6000KG |

| Equipment size | 6000mm×3000mm×2500mm(L×W×H) |

Copyright © 2014-2026 yingchuangjixie.com. All Rights Reserved.

Add:Caterpillar Industrial Zone, Qingzhou City, Shandong Province. Tel:0086 536 2136088